Updated : 04 August 2019

Laboratory’s name: WORKSHOP N08

| Bil. | Name of Instrument | Image of instrument | Contact person |

| 1. |

Shear cutting machine Shearing machines are multipurpose devices used in the cutting of alloys and other sheet metal (MAX 3mm). Some shearing machines use a scissor-like, angular shear action to cut metal into sheets or strips. Other, larger machines use a straight shear action with the blade fixed at an angle as opposed to the angular movement. |

|

Mohd Zarimi bin Ibrahim

|

| 2. |

Lathe Machine A lathe is a machine tool that rotates the workpiece on its axis to perform various operations such as cutting, sanding, knurling, drilling, or deformation, facing, turning, with tools that are applied to the workpiece to create an object with symmetry about an axis of rotation. |

|

Mohd Zarimi bin Ibrahim

|

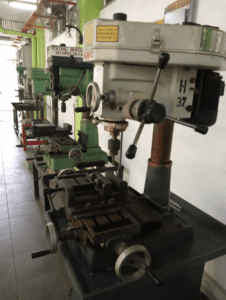

| 3. |

Milling Machine Milling machine is used in shaping flat and irregular surfaces. Aside from this main function, the milling machine can also perform other tasks such as drilling, routing, planning, cutting gears, boring, and producing slots among others. |

|

Mohd Zarimi bin Ibrahim

|

| 4. |

Vertical Bandsaw Cutting A vertical bandsaw, also called a contour saw, keeps the blade’s path stationary while the workpiece is moved across it. This type of saw can be used to cut out complex shapes and angles. The part may be fed into the blade manually or with a power assist mechanism. |

|

Mohd Zarimi bin Ibrahim

|

| 5. |

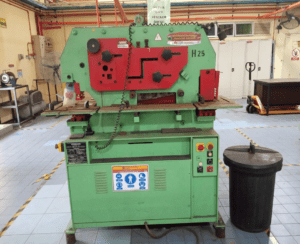

Cutting and Punching Machine The machine is using Punching principle. The concept of punching designates a slitting process in which a sheet is severed in one stroke. Shapes such as round holes are created in the part, and external contours are cut with single strokes |

|

Mohd Zarimi bin Ibrahim

|

| 6. |

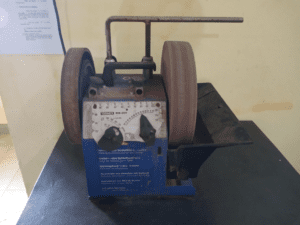

Grinding and Polishing Drill Bit A grinding machine, often shortened to grinder, is any of various power tools or machine tools … Grinding machines remove material from the work piece by abrasion, which can … Tool and cutter grinder, which usually can perform the minor function of the drill bit grinder, or other specialist toolroom grinding operations. |

|

Mohd Zarimi bin Ibrahim

|

| 7. |

MIG Welding Machine MIG welding is an arc welding process in which a continuous solid wire electrode is fed through a welding gun and into the weld pool, joining the two base materials together. A shielding gas is also sent through the welding gun and protects the weld pool from contamination. In fact, MIG stands for metal inert gas. |

|

Mohd Zarimi bin Ibrahim

|

| 8. |

Air Plasma Cutting Machine Plasma cutters work by sending an electric arc through a gas that is passing through a constricted opening. The gas can be shop air, nitrogen, argon, oxygen. As the metal being cut is part of the circuit, the electrical conductivity of the plasma causes the arc to transfer to the work |

|

Mohd Zarimi bin Ibrahim

|

| 9. |

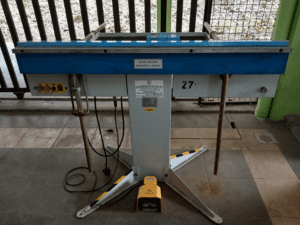

Electromagnetic Sheetment The fundamental Principle of the Magnetic Bending Machine is that it uses electromagnetic, rather than mechanical, clamping system. The machine consists of a long electromagnet with a steel clamp bar located above it. |

|

Mohd Zarimi bin Ibrahim

|

| 10. |

Horizontal Power Bendsaw A horizontal band saw is a type of band saw where the cutting piece stays stationary and the cutting head pivoting on one end cuts into the part by gravity assist. The Horozontal Band Saw can be used to rough cut metal or plastic (NO WOOD) stock to length. |

|

Mohd Zarimi bin Ibrahim

|

| 11. |

Multi-purpose Drilling Milling Machine Drilling machines, also called drill presses, cut holes in metal with a twist drill. They also use Drill presses for occasional use in general-purpose machine shops usually has only one spindle. For drilling several holes successively or simultaneously in a workpiece, machines with multiple spindles are available |

|

Mohd Zarimi bin Ibrahim

|

| 12. |

Arc Welding Machine It is a type of welding that uses a welding power supply to create an electric arc between a metal stick (“electrode”) and the base material to melt the metals at the point of contact. Arc welders can use either direct (DC) or alternating (AC) current, and consumable or non-consumable electrodes. |

|

Mohd Zarimi bin Ibrahim

|